Let me ask you a question - how do you manage your orders?

As an omnichannel or high-volume DTC brand, your technology can be the achilles heel in your fulfillment operation. If your order data is inaccurate or even not up-to-date, you’re making faulty inventory decisions, recovering from mishandled and delayed fulfillment, and facing angry customers.

Having worked with some of the fastest growing DTC and omnichannel businesses, we have encountered a LOT of “solutions.” While we won’t be digging into the different approaches brands have classically employed (look for more on that topic soon), let’s instead discuss three of the critical capabilities an order management system (OMS) should provide for a modern operation.

(And If you want to have a comprehensive list of everything you need, skip this entire blog post and download our official checklist “What Your Order Management System Should Be Doing.”)

1. Multichannel Inventory Management

Traditionally, brands needed to have discreet and physically distinct inventories for every sales channel - e.g., a different pool for Amazon, QVC, Walmart, their storefronts and websites, etc.

While this old school system seemingly lets you “manage” inventory easily, it is rigid, inefficient and costly, and will break under sudden demand spikes. And in fact, most systems really only let you report on your inventory and not truly manage it, particularly when issues arise.

For example, if you run a sale on your website and see a huge demand spike, what happens if you run out of that channel’s inventory for a given SKU? Often, you are forced to show out-of-stock messaging and miss out on positively servicing customers – and earning revenue.

With multichannel inventory management, you can set automated rules or workflows to pull inventory (or reserve it) without needing manual intervention to physically separate your inventory or tie up cash in excess inventory for every channel. This capability also lets you reserve inventory for key accounts and partners, prioritizing inventory for their orders via reservations.

You can react faster by managing inventory shortage behavior based on sales channel or other order attributes. And with cross-channel inventory visibility, you can eliminate overselling and under-delivering, ensuring a consistent and satisfying customer experience.

2. Rapid System Connectivity

Your demand is growing, yay! You are opening up new sales channels and big box retail partners to meet that demand, also yay! And it will take you weeks to connect them to your existing systems, and to onboard another 3PL…not so much yay.

Traditionally, brands were unable to avoid lengthy setup times when bringing on new sales channels or partners. And sometimes, integration was jury-rigged or even impossible, leaving brands with disjointed dashboards, out-of-date data and siloed systems - forcing them to try and cobble together a comprehensive picture of their orders and inventory (let alone a real-time one!) through a painstaking process of paper reports, Excel spreadsheets, and sticky notes.

A modern OMS not only should let you integrate with your existing – and any future channels/partners – but also connect with them quickly…in days, not months. And not break the bank in the process!

You often get one chance to impress a new customer or retail partner with the sales experience; it shouldn’t suffer because you are waiting for a developer to finish coding a custom integration in 2-3 months.

3. Single Consolidated Dashboard

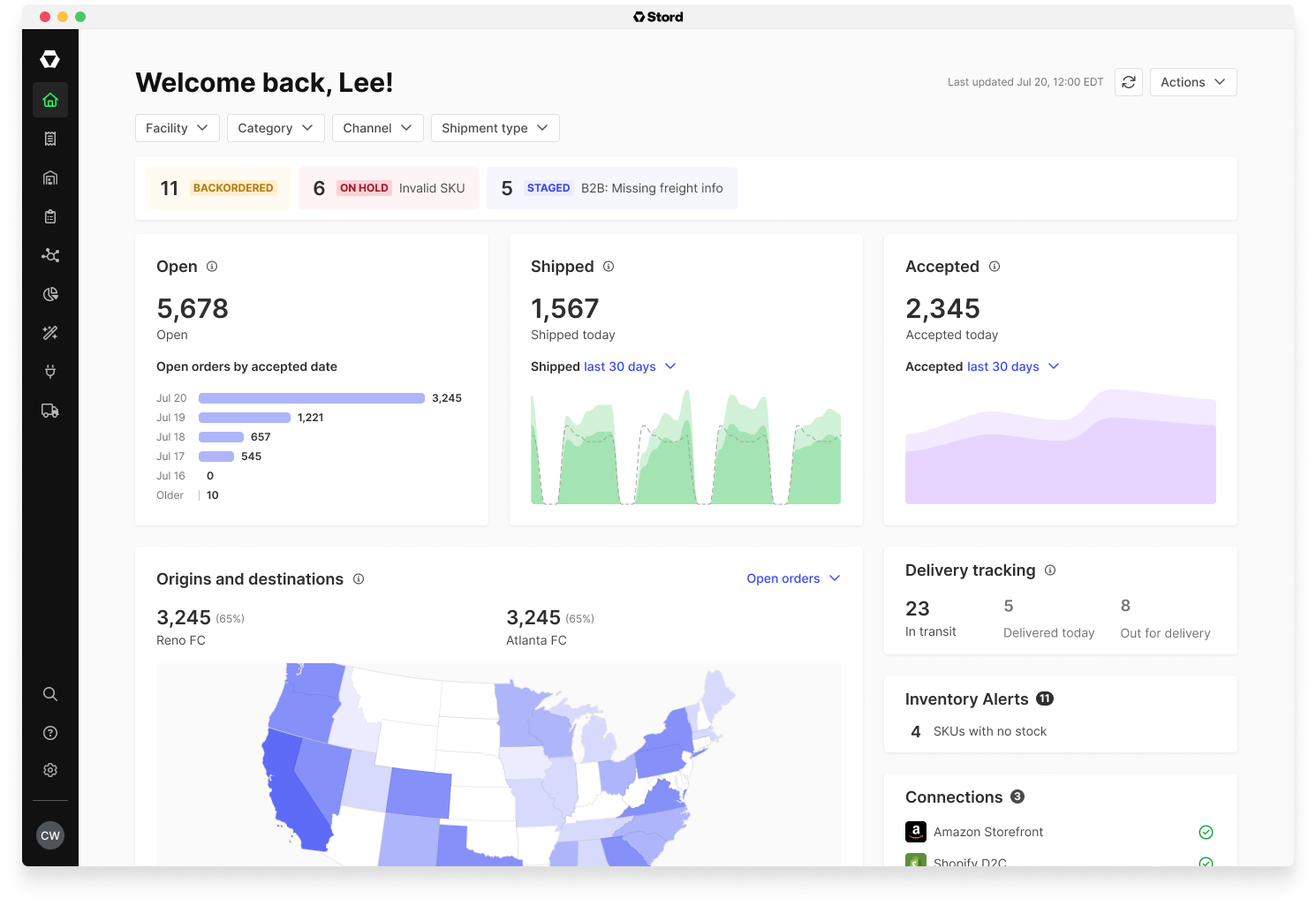

With the advent of rapid connectivity, another powerful benefit of a modern OMS reveals itself - a single consolidated dashboard.

When all of your systems integrate, your OMS provides a single record of truth for the status of all orders and every single item within your inventory. This record is accurate regardless of which pool it was earmarked for or in which warehouse it is currently located.

Simply put, brands have a single, real-time snapshot of every pending, in-progress, and delayed order across their entire ecosystem of 3PLs and in-house fulfillment centers. It’s the only way to ensure you’re fully on top of every order - and can respond to issues - before your customers do!

While these three things are incredibly important, there are another nine things your order management system SHOULD be doing, and you can read them all here.